Okulandelayo umehluko omkhulu phakathi kwe-lean tube yesizukulwane sesithathu namaphrofayili e-aluminium wangaphambilini:

Okubalulekile

I-tube lean yesizukulwane sesithathu: Yenziwe nge-aluminium alloy, ehlanganisa izinzuzo zesisindo esilula, amandla aphezulu, nokumelana nokugqwala okuhle.

Amaphrofayili e-aluminium adlule: Ngokuvamile abhekisela kumaphrofayili e-aluminium endabuko, angase abe nokuqanjwa okulula kwe-alloy noma ukwelapha okungaphezulu uma kuqhathaniswa neshubhu le-lean lesizukulwane sesithathu.

Ukwelashwa kwendawo

Ithubhu ethambile yesizukulwane sesithathu: Indawo engaphezulu ivamise ukuphathwa nge-anodizing, enganikeza ukumelana nokugqwala okungcono, ukumelana nokugqokwa, nokubukeka okuhlala isikhathi eside nokujabulisa ngobuhle. Le filimu ye-anodic oxide ingaphinda ithuthukise ubulukhuni nokumelana nokuklwebheka kwendawo, ikwenze ifaneleke kakhulu ukusetshenziswa ezindaweni ezahlukahlukene.

Amaphrofayili e-aluminium adlule: Angase abe nezindlela ezahlukene zokwelashwa kwendawo efana ne-electrophoresis, i-powder coating, noma ukupholisha ngomshini. Nakuba lezi zindlela zokwelapha zingase futhi zithuthukise ukubukeka nokumelana nokugqwala ngokwezinga elithile, ukusebenza nokuhlala isikhathi eside kungase kungabi kuhle njengokwelashwa kwendawo egcotshiwe yeshubhu yesizukulwane sesithathu esinciphile.

Idizayini yesixhumi

I-tube lean yesizukulwane sesithathu: Izixhumi nezixhumi zayo zithuthukisiwe, ngokuvamile zenziwe nge-die-cast aluminium impahla, ethuthukisa ubulukhuni nokuqina. Idizayini yezixhumi isebenziseka kalula, okwenza kube lula ukulayisha nokuyikhipha, futhi ingaxhunywa ngokushesha futhi iboshwe ezingxenyeni zezinkampani zangaphandle. Lokhu kuvumela ukuhlanganisa nokuhlakazeka okulula, ukuthuthukisa ukusebenza kahle komsebenzi nokuguquguquka ngesikhathi sokufakwa nokugcinwa.

Amaphrofayili e-aluminium yangaphambilini: Izixhumi zamaphrofayili e-aluminium yendabuko zingase zingabi nawo ukwakheka okuthuthukile nokukhetha kwezinto ezibonakalayo, futhi zingadinga amathuluzi namasu okufaka ayinkimbinkimbi ngesikhathi sokuhlanganisa. Kwezinye izimo, ukucubungula okwengeziwe noma ukulungiswa kungase kudingeke ukuze kuqinisekiswe ukuxhumana okuqinile, okungase kwandise isikhathi sokufaka nezindleko zomsebenzi.

Isisindo

Ithubhu le-lean lesizukulwane sesithathu: Ngenxa yokusetshenziswa kwezinto ze-aluminium alloy kanye nomklamo olungiselelwe, isisindo seshubhu elilodwa le-aluminium silula kakhulu kuneshubhu elilodwa lendabuko elithambile noma amanye amaphrofayili e-aluminium adlule. Lokhu kwenza amabhentshi okusebenza ahlanganisiwe, amashalofu, noma ezinye izakhiwo ezenziwe ngamashubhu esizukulwane sesithathu anciphile abe lula ngesisindo, okuzuzisa ukuphatha kalula, ukuthutha, nokuthuthwa.

Amaphrofayili e-aluminium yangaphambilini: Kuye ngohlobo oluthile nobukhulu, isisindo samaphrofayili e-aluminium yangaphambilini singahluka, kodwa ngokuvamile, singase sibe nzima kakhulu uma siqhathaniswa ne-tube yesizukulwane sesithathu esinciphile, ikakhulukazi uma kucatshangelwa isakhiwo sonke ngemva komhlangano.

Izimo zohlelo lokusebenza

I-tube lean yesizukulwane sesithathu: Ngenxa yesisindo sayo esilula, ukumelana nokugqwala, kanye nokuhlangana kahle, isetshenziswa kabanzi ezimbonini ezifana nokukhiqiza izinto zikagesi, ezemithi, ukucubungula ukudla, kanye nokugcinwa kwempahla, ikakhulukazi ezimeni lapho kudingeka khona ukulungiswa okuvamile noma ukuthuthwa kwemishini, njengemigqa yokukhiqiza kagesi, izindawo zokusebenzela ezihlanzekile, nezindawo zokusebenzela ezihlanzekile.

Amaphrofayili e-aluminium adlule: Aphinde abe nezinhlelo zokusebenza eziningi ezahlukene, okuhlanganisa ukwakhiwa (okufana neminyango, amafasitela, nezindonga zamakhethini), ukukhiqizwa kwezimoto, ukukhiqizwa kwemishini yemishini, neminye imikhakha. Kwezinye izinhlelo zokusebenza lapho amandla aphezulu kanye nokuqina kuyadingeka, njengohlaka lwemishini esindayo noma ukwakheka kwezakhiwo ezinkulu, amaphrofayili e-aluminium aqinile nanamandla angasetshenziswa.

Izindleko

Ithubhu ethambile yesizukulwane sesithathu: Ngokuvamile, inqubo yokukhiqiza kanye nezindleko zempahla yethubhu lean yesizukulwane sesithathu kungase kuthuthukiswe ngokuqhathaniswa, okuholela enanini eliqhudelana kakhulu emakethe. Ngesikhathi esifanayo, impilo yayo ende yesevisi kanye nezindleko zokunakekelwa okuphansi nakho kuyenza ingabizi kakhulu ngokuhamba kwesikhathi.

Amaphrofayili e-aluminium adlule: Izindleko zamaphrofayili e-aluminium yangaphambilini zingahluka kuye ngezinto ezifana nohlobo lwengxubevange, ubuchwepheshe bokucubungula, nokwelashwa kwendawo. Amanye amaphrofayili e-aluminium asebenza kahle kakhulu noma anenhloso ekhethekile angase abe nezindleko eziphakeme uma kuqhathaniswa, kuyilapho amanye amaphrofayili avamile e-aluminium engase abe nezintengo ezinzile. Nokho, uma kuqhathaniswa neshubhu lean lesizukulwane sesithathu, angase angabi nazo izinzuzo ezisobala mayelana nokusebenza kwezindleko kwezinye izimo zohlelo lokusebenza.

Isevisi yethu eyinhloko:

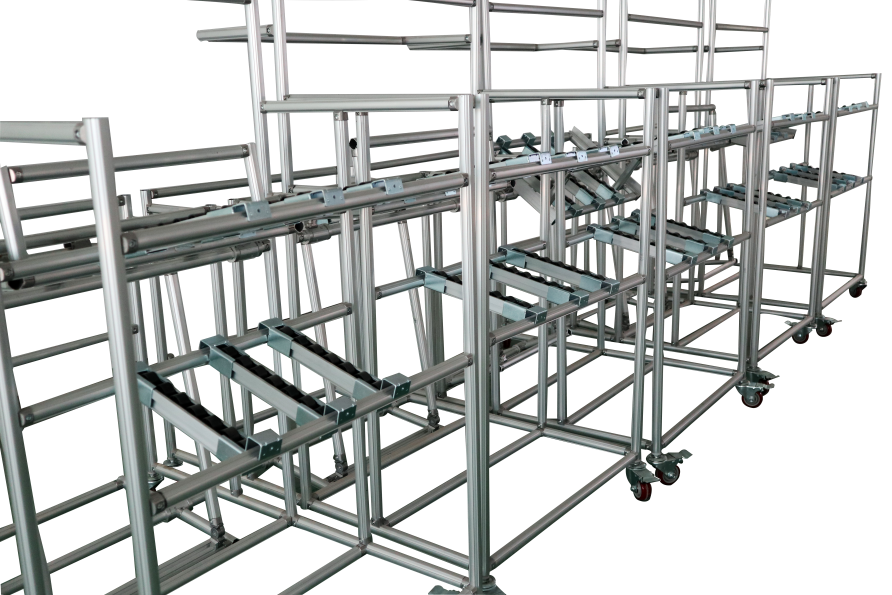

·I-Heavy Square Tube System

Siyakwamukela ukucaphuna amaphrojekthi akho:

Contact: zoe.tan@wj-lean.com

Whatsapp/ifoni/Wechat : +86 18813530412

Isikhathi sokuthumela: Nov-28-2024